Business

As the innovation base of key common technologies in China’ metallurgical industry, CISRI has successively presided over more than 50% of the R&D tasks of major key and common technologies in the iron & steel industry in technological innovation of iron a

Low Carbon Ironmaking

Performance/Technology

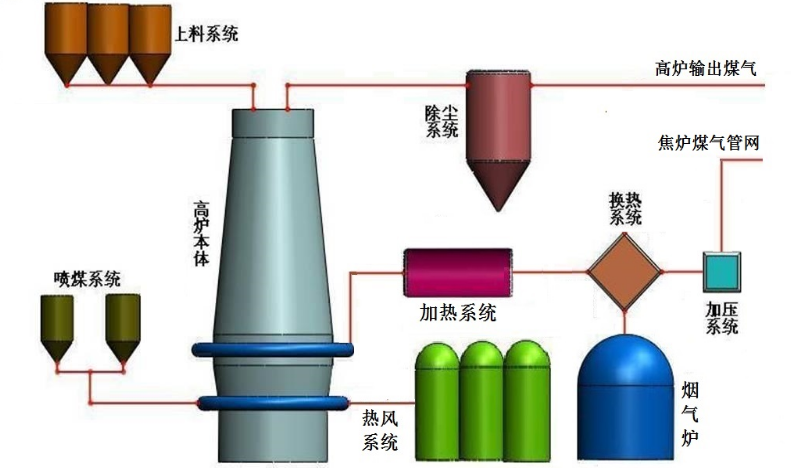

With the increasing shortage of coking coal resources, developing a new process of non-blast furnace ironmaking with coal instead of coke is an important means to reduce costs and increase efficiency in ironmaking. The one-step smelting reduction researched and developed by CISRI adopts the direct smelting of fine ores and pulverized coals, which saves the pre-iron agglomeration and coking processes, and the total capital construction cost is significantly lower than that of the blast furnace ironmaking method. One of the new generation low-carbon green smelting technologies researched and developed by CISRI is to achieve energy conservation, emission reduction and consumption reduction by injecting coke oven gas.

Learn moreRelated products

读取内容中,请等待...

英文网

英文网